Solutions

AFMING 5 Axis Machine

Afming five-axis machining technology can be continuous, faster and more direct, with better results so it is widely used in aircraft, molds, mechanical parts, titanium parts, artificial bones and other products. It provides appropriate accessibility for cutting and shaping of complexed parts.

Afming CNC machine centers are the best choice when you are dealing with different materials, complex parts and considerable workloads. With the industry’s leading machine technology and quality, Afming promises high quality and efficiency.

5 axis Machine Solution

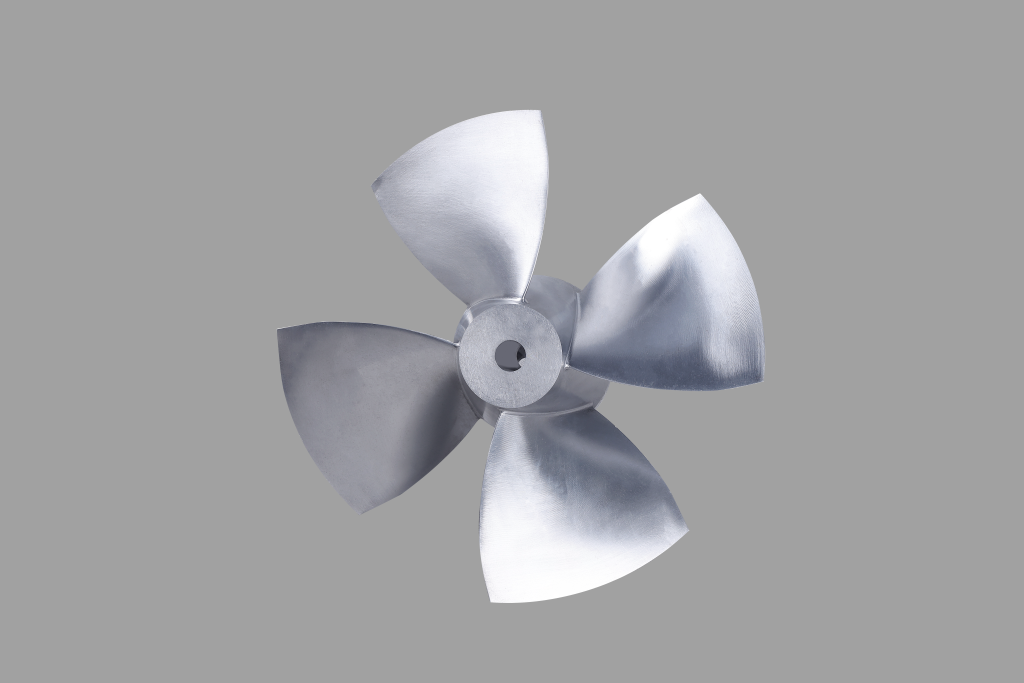

Afming 5-axis machine solutions are widely used in the oil and gas, automotive, aerospace, compressor machining, medical, robotics, marine and alternative new energy industries.

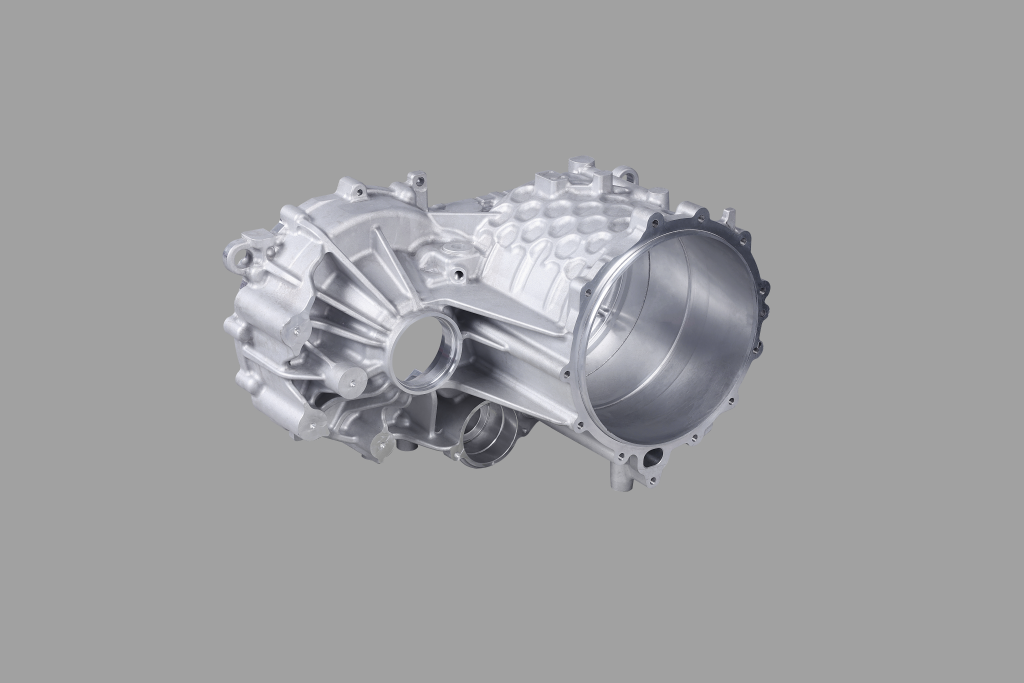

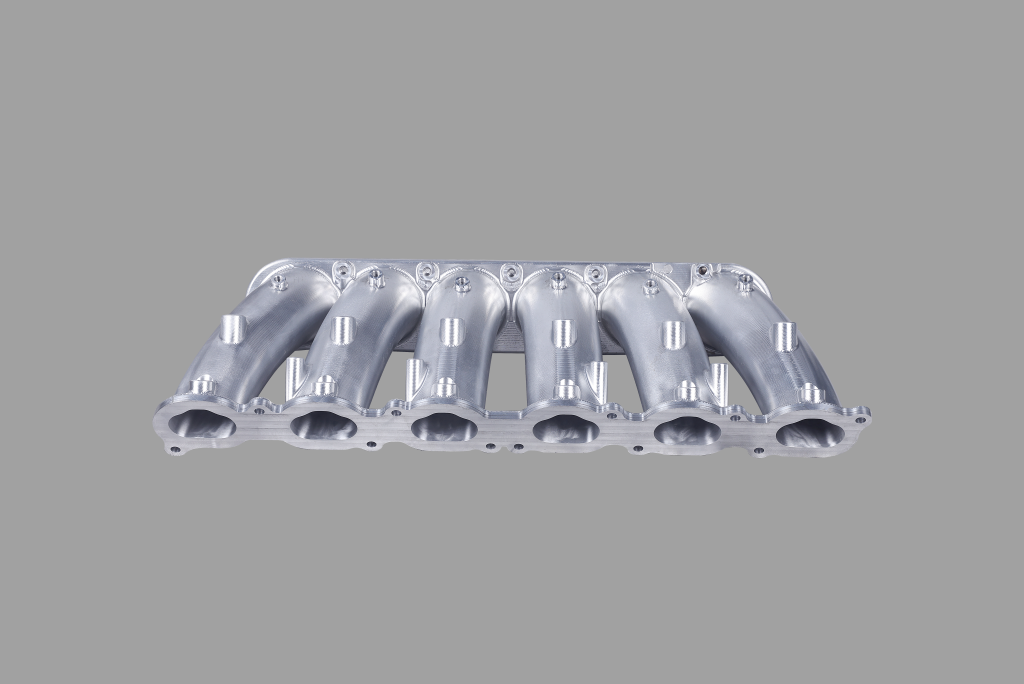

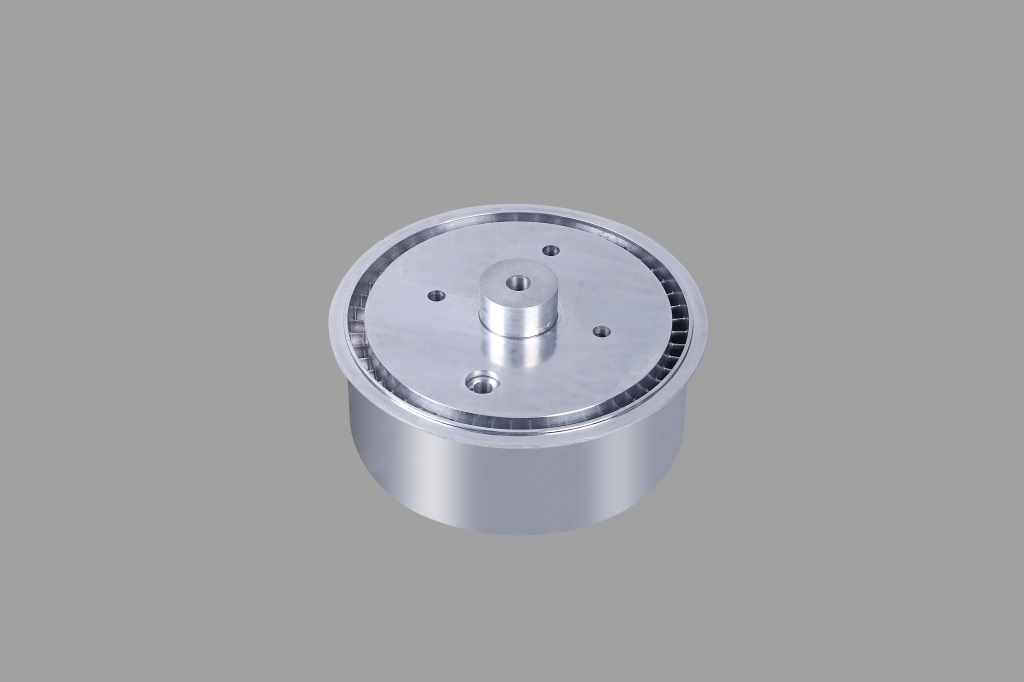

Car Industry

Five-axis machining is perfect for manufacturing complex, high-precision and high-strength parts for automotive parts. In order to ensure the correct fit of mechanical parts, the precision requirements for automobile parts are very high. The application of this technology can enable the automotive industry to develop in scale, efficiency and personalization.

Used to manufacture cylinder blocks and crankshafts of

engines, automobile chassis and suspension systems.

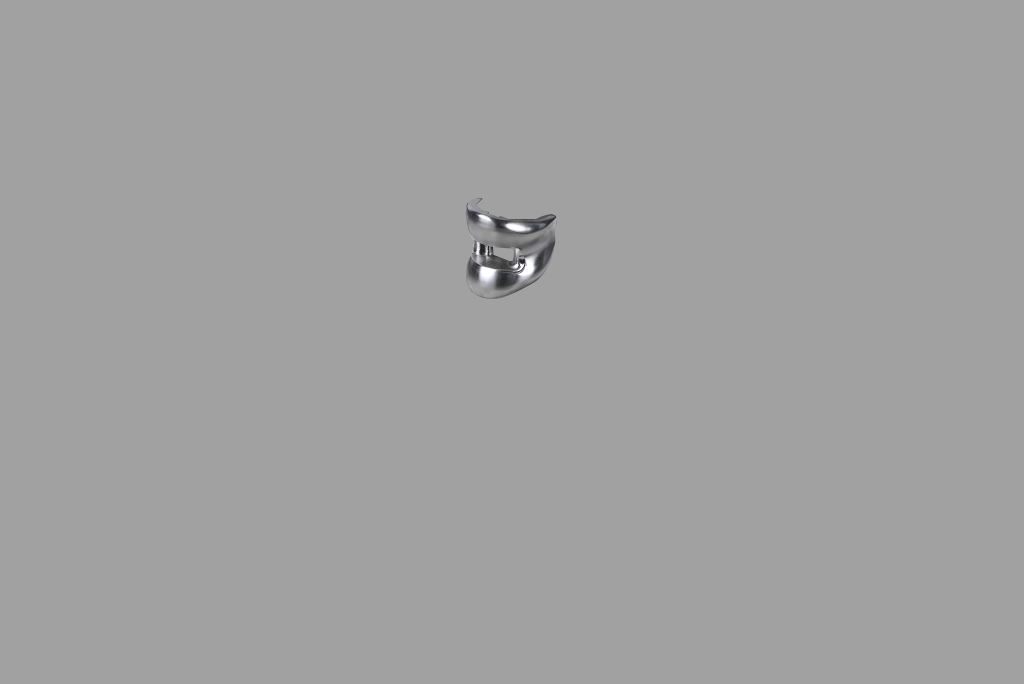

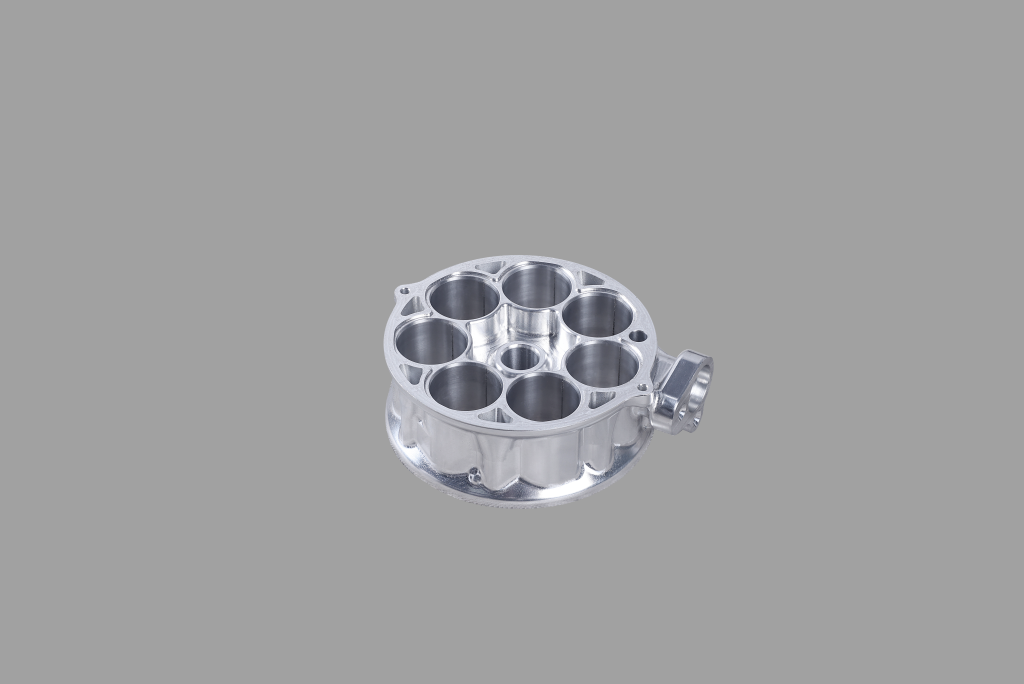

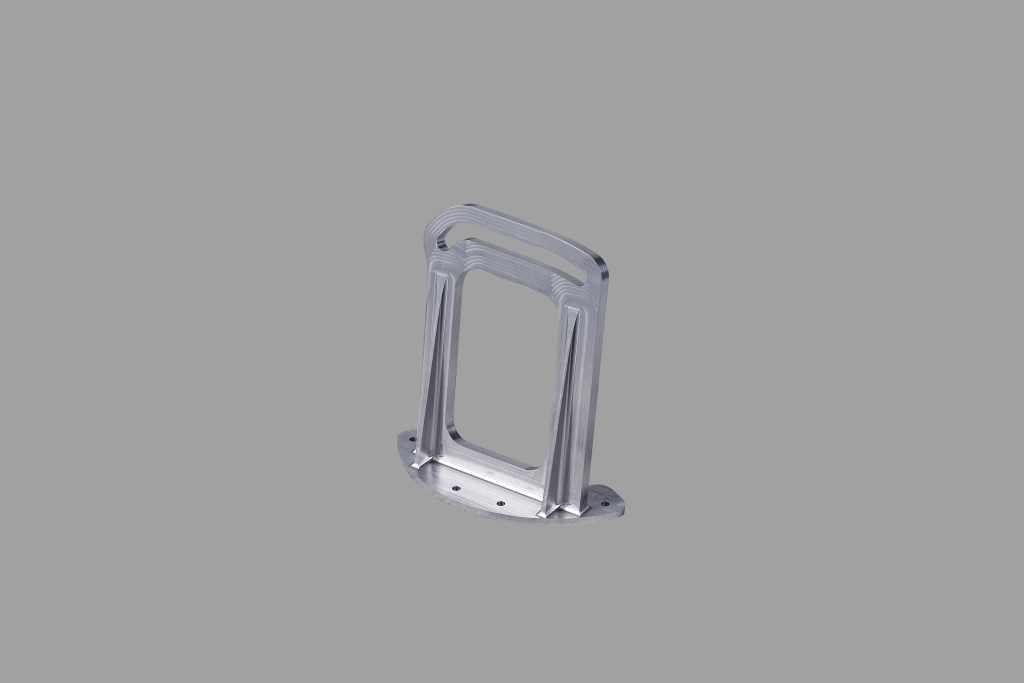

Medical Industry

Medical parts and tools need to be designed with sufficient precision to ensure that the elements used for surgery or replacement parts fit perfectly. Improper cuts or imperfect edges can render medical supplies unusable. This makes five-axis machining the preferred way to create custom medical tools and components.

Used to manufacture medical device parts such as artificial joints and cardiac membranes.

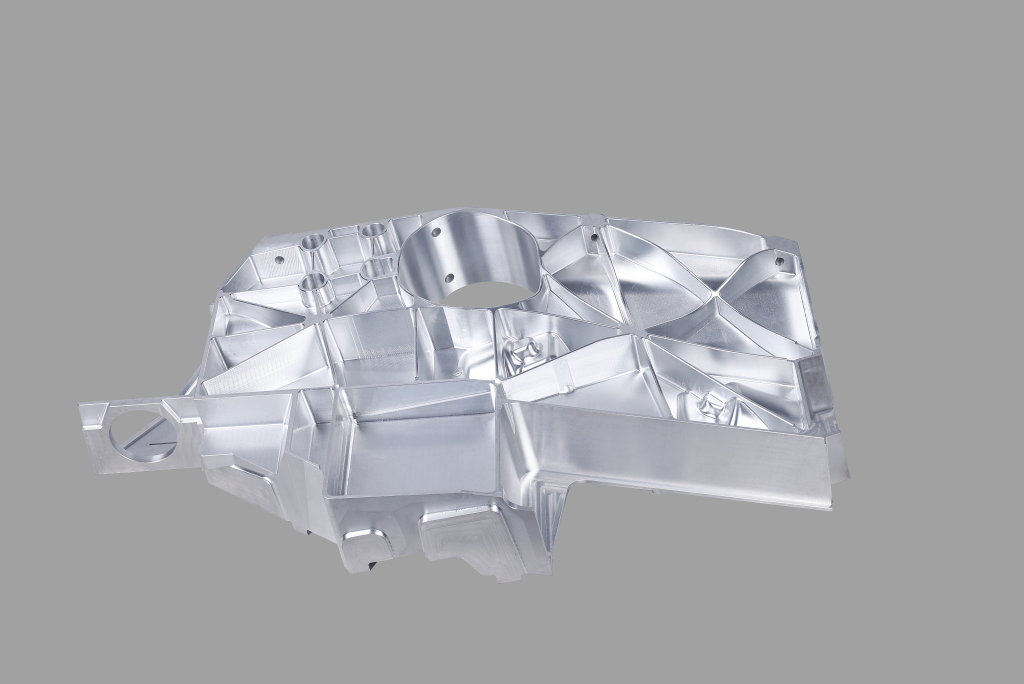

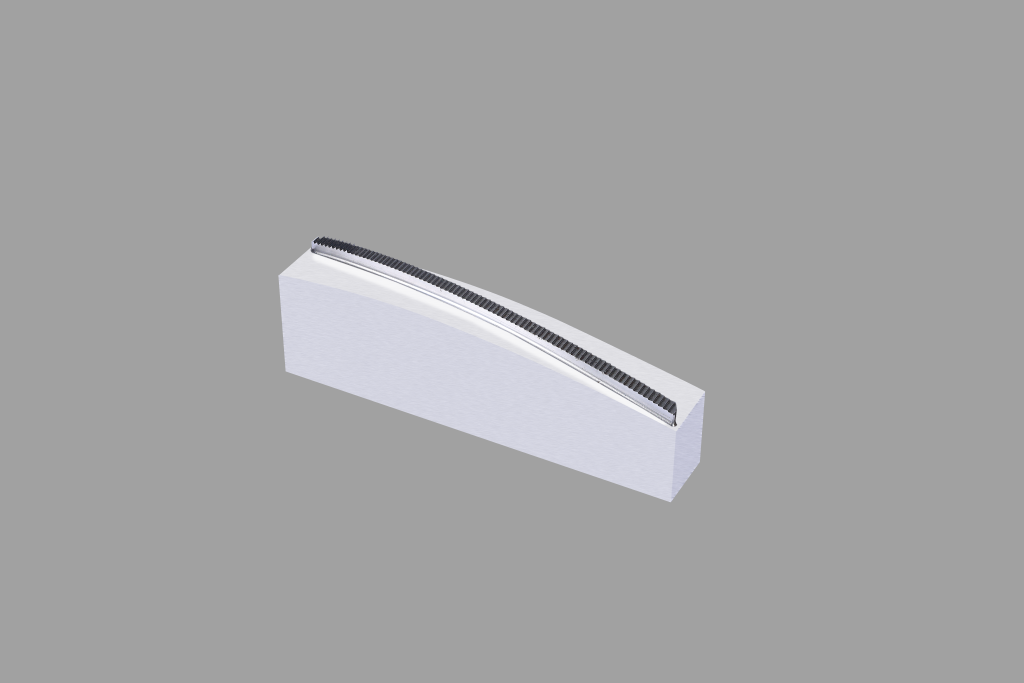

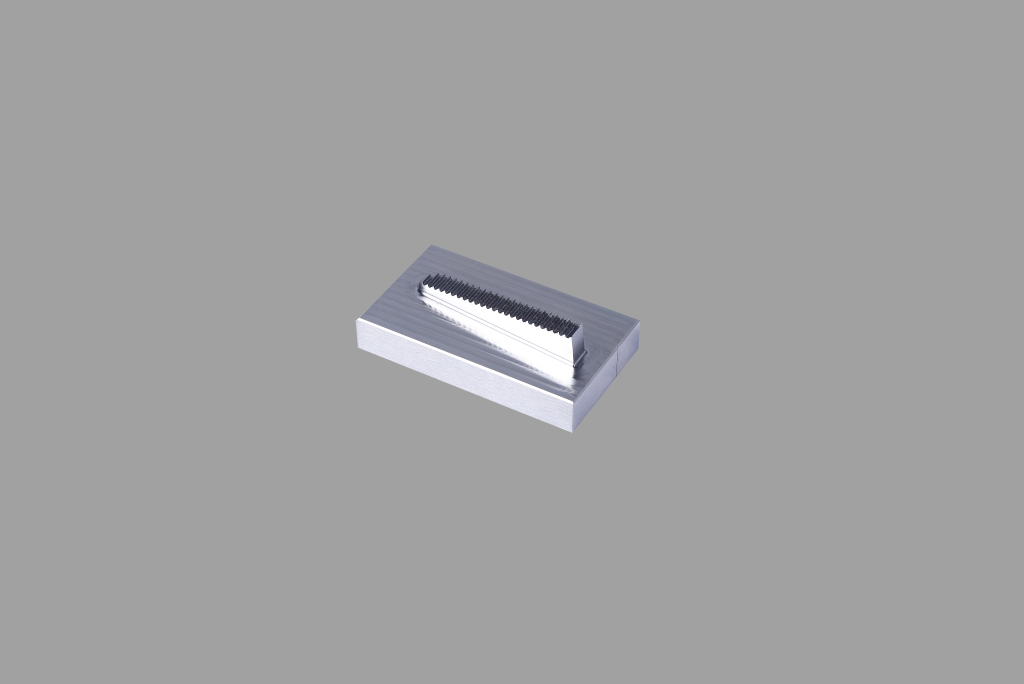

Mold manufacturing industry.

Five-axis machining center can achieve one-time processing of complex shapes through the linkage control of its five axes, greatly improving processing efficiency and accuracy. Greatly reduce the number of tool changes and clamping and shorten the production cycle, and reduces production costs.

Five-axis machine solution is used to manufacture injection molds, die-casting molds, etc., achieving efficient and high-precision machining.

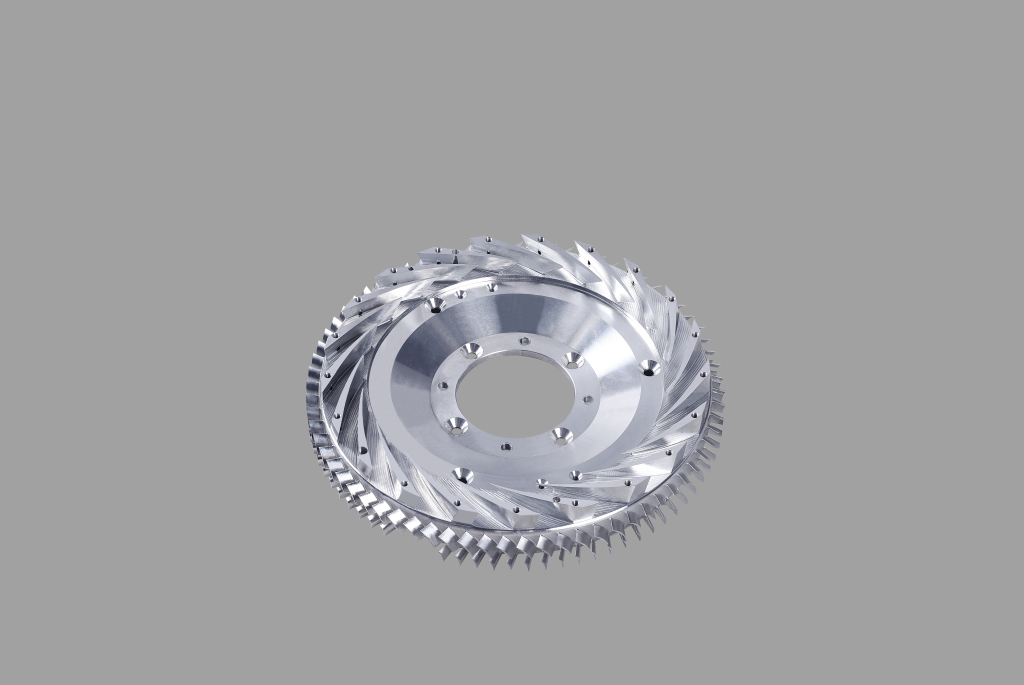

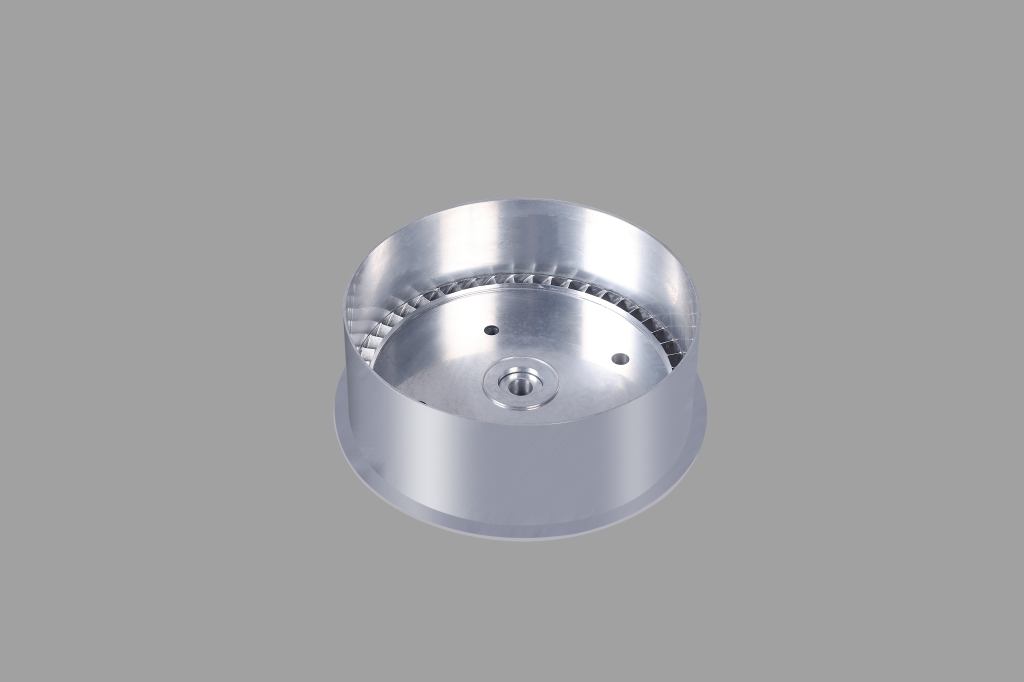

Aerospace industry

The precision required by the aerospace industry for aircraft, rockets, satellites, etc. can directly impact human life. Poorly made parts on a flying machine can prevent systems from working properly, leading to manufacturing defects that could cause a crash.

Five-axis machining can efficiently complete the processing of complex parts such as turbines, blades, and casings of aircraft engines, rocket engine nozzles and satellite antennas.

The best choice would be Afming 5-axis Machine, There are more 5 axis machine solution for you!