How about our DMU400 Five-axis Simultaneous Machining Center ?

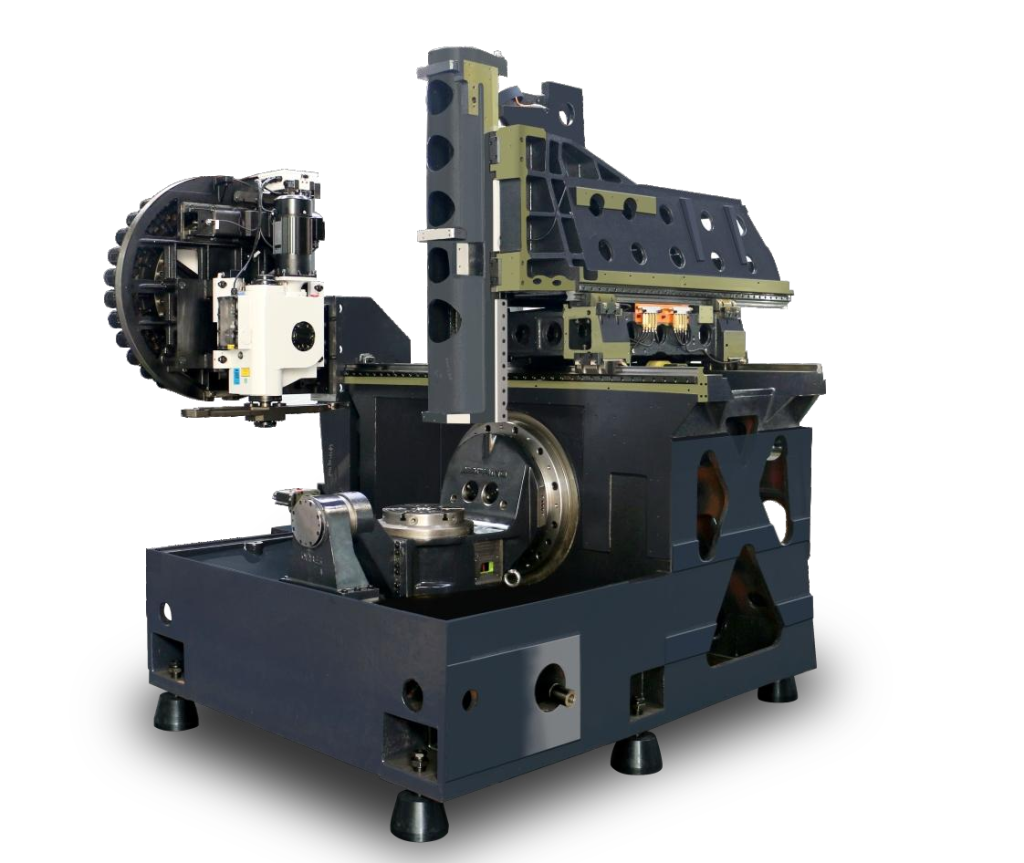

The DMU400 five-axis simultaneous machining center adopts a cantilever structure and is equipped with the DD drive cradle-type rotary worktable independently developed by AFMING.

It has excellent rigidity, fast response, and stable accuracy, and can easily handle the efficient processing of small precision parts such as medical equipment and new energy sources.

DMU400 Five-axis Machining Center Advantages:

1, The three axes are cantilever structures

The DMU400 five-axis linkage machining center adopts a reinforced cantilever structure. And the X/Y/Z axes are placed on the upper part of the bed. In addition, the basket turntable rotates around the Y-axis as the B-axis and around the Z-axis as the C-axis.

- + X/Y/Z axes are all driven by high-response nut rotating ball screws, which effectively prevents thermal extension of the screws and ensures accuracy and stability.

- + The cradle-type rotary table is designed and manufactured by our company. The B/C axes are all driven by DD motor direct drive, with oil cooling circulation as standard. The brakes use high-pressure oil to drive large-size disc brakes, with high precision and long life.

- + X/Y/Z axes all use high-rigidity 35-type P-level roller guides to reduce friction and improve accuracy.

- + X/Y/Z axes all use ball screws with a diameter of 40mm, a lead of 20mm, and a rapid movement speed of 40m/min.

Acceleration 1G.

- + The Z-axis adopts high-precision, high-speed air pressure counterweight, which responds efficiently, effectively eliminates the influence of gravity, reduces the thermal elongation of the screw rod, and effectively improves the service life and accuracy of rolling parts.

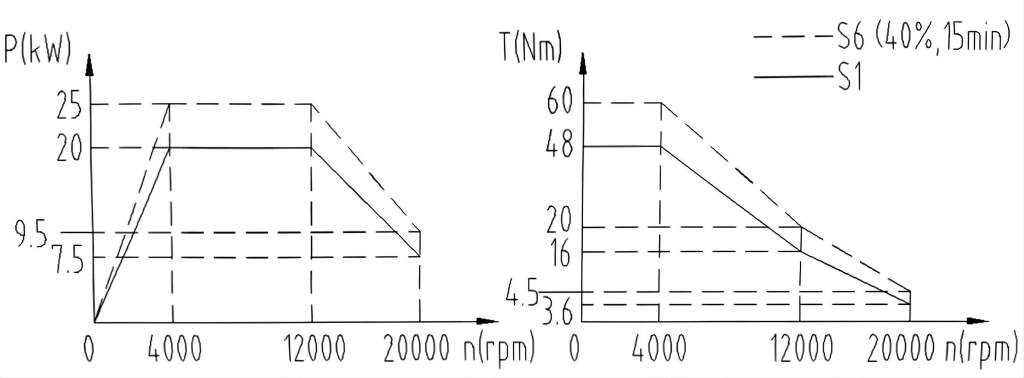

2, High rigidity electric spindle

the 5 axis machining center is equipped with 20000 rpm electric spindle HSKA68、BBT40. Hence it fully considers special processing conditions such as various parts processing and mold processing, and provides customers with customized spindle solutions to expand the processing range. Improve processing efficiency.

- + Permanent magnet synchronous double coil spindle technology saves more than 12% of energy.

- + More stable axial dimensions.

- + HSK- A63 shaft end interface, high precision, high rigidity, high speed.

| 20000 rpm electric spindle HSK-A68/BBT40 | |

| 20/25 kW | Power (S1/S6-40%) |

| 48/60 N.m | Output torque(S1/S6-40%) |

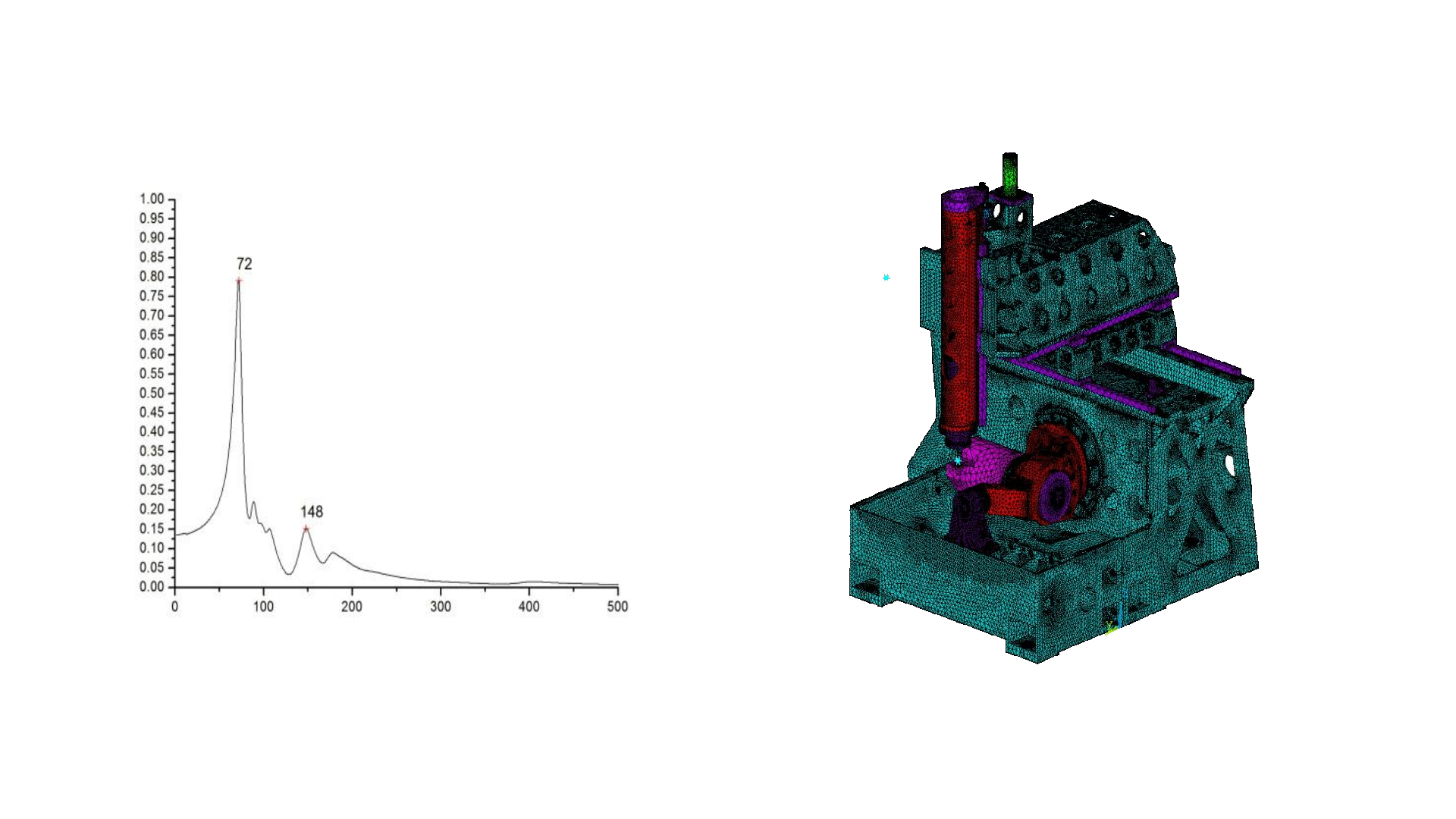

3, Finite element analysis and dynamics optimization are used to greatly improve the performance of the entire machine.

- + Dynamic optimization through FEA, effectively improve the anti-vibration of the whole machine.

- +Accurately calculate the optimal dynamic rigidity under actual working conditions.

- +Improve the natural frequency and cutoff frequency of the feed drive system, effectively reduce the positioning time and the lag of the feed system to achieve high response dynamic performance and high- speed machining profile accuracy.

4, HEDENHAIN CNC Control

The 5 axis machine tool adopts HEDENHAIN – ITNC640 system, spindle drive unit, feed drive unit, AC spindle electric AC feed servo motor are all original feed, advanced performance, stable and reliable.

Operating system Machine tool CNC system, HEROS real-time operating system

- + Input resolution and display step linear axis: up to 1 Lm

- + Rotary axis: up to 0.001 o

- + Input range up to 999 999 999 mm or 999 999 999

- + Interpolation 4-axis linear interpolation, including spindle.

- + Option 9 – 2-axis circular interpolation.

- + Block processing time 0.5 ms (3-D linear without radius compensation)

- + Error compensation linear and nonlinear errors, backlash, reverse angle of circular motion, thermal expansion and static friction.

- + Data interface RS-232-C/V.24 and RS-422/V.11 each, maximum speed 115 kbps.

- + Diagnostics Self-contained diagnostic tool for fast and easy troubleshooting.

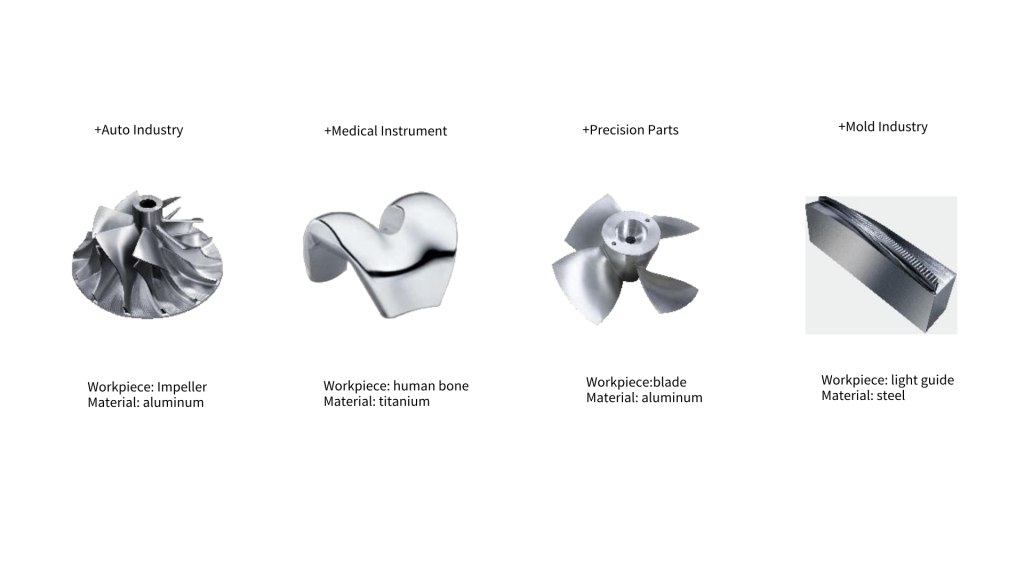

DMU400 Five-axis Machining Center Application:

The machine frame has excellent rigidity and sensitive movement, and can easily cope with the requirements for efficient and high- precision machining of parts and molds made of various materials.

Main Specifications of DMU400 Five-axis Simultaneous Machining Center

| Name | Unit | DMU400 | |

| Workbench and single pendulum head | X/Y/Z-axis travel | mm | 586(including too change)/370/350 |

| B/C-axis travel | degree | +110 to-5/360 (infinite) | |

| Worktable size/maximum load capacity | mm/kg | φ350/100(evenly distributed) | |

| Max.clamping diameter of worktable | mm | O350 | |

| Spindle nose to table surface | mm | 136-486 | |

| B-axis rated torque/brake torque | N.m | 860/2000 | |

| C-axis rated torque/brake torque | N.m | 205/600 | |

| Spindle | Maximum spindle speed/ tapered shank | Rpm/Knife shank |

20000/HSK-A63 |

| Spindle power (S1/S6-40%) | kW | ||

| Spindle torque (S1/S6-40%) | N.m | ||

| Feeding system | X /Y/Z axis rapid displacement | m/min | 40/40/40 |

| Maximum cutting feed rate | m/min | 20 | |

| B/C axis fast forward speed | RPM/min | 80/150 | |

| Positioning accuracy / repositioning

accuracy-(ISO 10791-4:1998) |

X/Y/Z axis positioning accuracy | mm | 0.008/0.008/0.0008 |

| X/Y/Z axis repeated positioning accuracy | mm | ||

| B/C | ARCSEC | 4/4 | |

| Automatic tool change system | Number of tools | PCS | 30T |

| Tool change time (knife-knife) | sec | 3 (Depending on the spindle loose-clamping tool and other factors vary) | |

| Max.tool length | mm | 250 | |

| Maximum tool diameter/adjacent no tool |

mm | φ75 /φ120 | |

| Max.tool weight | kg | 8 | |

| Machine weight | About 6 tons | ||

| Machine appearance size (L×W) | About 3860×3445 mm | ||

| Power demand | kw | ||

DMU400 5 axis Machining Center Standard/Optional

| NO. | Main standard configuration | Options Specification | ||

| 1 | System | Heidenhain iTNC 620 | HSK-A63 20000rpm ABIG spindle | Power:20/24 kw Torque:35/42 Nm |

| 2 | Sheet metal | Full-circle fuselage sheet metal (including water tank) | HSKA63-40T Tool magazine | |

| 3 | Spindle | HSK-A63-20000rpm AFMING Electric spindle | Hexagon laser tool setter | |

| 4 | B/C cradle turntable | DD rotation structure | Blum laser | |

| 5 | Spindle cooler | Water cooler(Tongfei) | CTS30 bar spindle center water outlet | |

| 6 | Three axis linear encoder | HEIDENHAIN | CTS50 bar spindle center water outlet | |

| 7 | B/C axis rotary encoder | HEIDENHAIN | CTS70 bar spindle center water outlet | |

| 8 | Tool setter | Marposs contact | Oil mist collector | DMU400-QS-750(Qiushan Machinery) |

| 9 | Tool magazine | 30T tool magazine | Automatic door | DMU400-Right automatic door component |

| 10 | Chip removal system | Spiral Type Chip Conveyor | Safety door lock | DMU400-Safety door lock components |

| 11 | Guide Rail | X-axis 35 roller guide,Y-axis 35 roller guide,Z-axis 35 guide | System Function Options | Five axis collision prevention |

| 12 | Wire Rod | X-axis R40 x 20, Y-axis R40 x 20, Z-axis R40 x 20 | Post processing services | UG NX Post processing(Heidenhain System) |

| 13 | Z-axis balancing system | Air pressure balancing system (SMC,Japan) | Post processing services | Hmp Post processing(Heidenhain System) |

| 14 | Electrical box thermostat system | Air conditioner constant temperature(Tongfei) | Post processing services | Powermill Post processing(Heidenhain system) |

| 15 | Pneumatic system | SMC,Japan | Post processing services | Mastercam Post processing (Heidenhain system) |

| 16 | Hydraulic Station | 7oceans,Taiwan | Post processing services | On machine measurement and compensation module |

| 17 | Automatic lubrication device | Liubian, Zhejiang | Post processing services | The Heidenhain system of NX software for online alignment and measurement |

| 18 | Processing area cleaning | Air gun and water gun for cleaning | ||

| 19 | Work light | LED lighting | ||

| 20 | Warning Light | Three-color warning light | ||

| 21 | Tool box and ground screws | Tool box and ground screws | ||

| 22 | 5-axis center alignment kit | (with 3D probe) Heidenhain | ||

| 23 | Reserved automation interface | |||

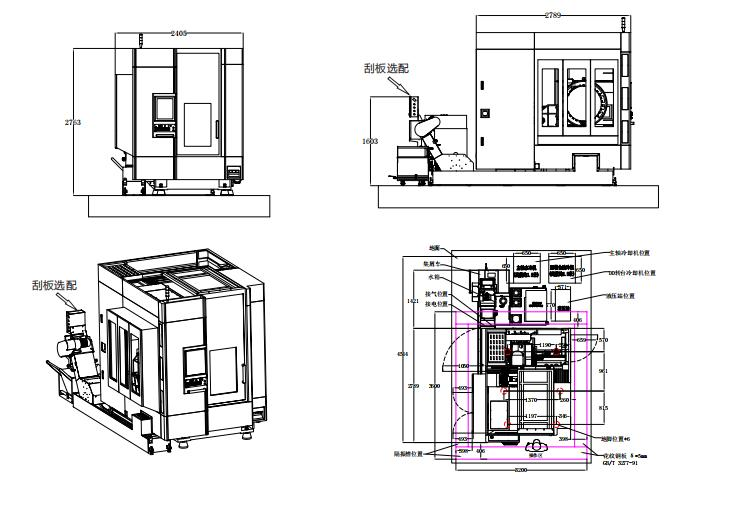

Machine Layout diagram (DMU-400)

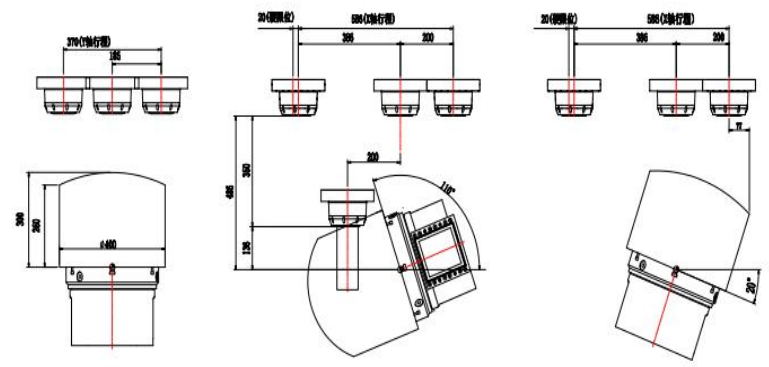

Machining Processing Interference Pattern(DMU-400)